Categories

Contact Us

Email :A.Alexandr@huazn.com

Phone/WhatsApp:

+7 903 008 6006

Address:

Moscow, Nizhegorodskaya Street 32s15, 5th floor, office 513

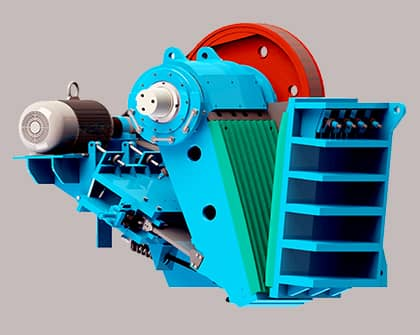

DHKS Stone Crusher

Feeding Size: 210-770mm

Processing Capacity: 7-500 t/h

Output Size: 20-80 mm, 90-250 mm for 120 types of stones

Model: small, medium and large models are in stock available

Processing Materials: limestone, granite, gravel, aggregate, rock, basalt, quartz, etc.

Customized Service: Small, medium and large models can be customized to meet your needs.

- Commodity name: DHKS Stone Crusher

- Описание продукции

-

Description

The Hot-sale Models and Capacity of Stone Jaw Crusher

1-30t/h, 60-80t/h, 80-100t/h, 100-150t/h, 200-400t/h, etc. are the hot-sale production capacity of jaw crusher. DHKS400×600, DHKS600×900, DHKS900×1200, DHKS1600*2000 are the hot-sale models.The fineness of the finished products are including different sizes and other specifications to meet your different needs.

Different types will be chosen according to your requirement such as the capacity, materials, input size, output size, and the cost. Small, medium and large-sized models can be chosen by you, so tell us your needs, and then our technical people will prepare the latest quotation and price list for you asap.

★The hot sale stone crusher model includes DHKS 400*600 jaw crusher, DHKS600*900 jaw crusher, PFQ 1110 impact crusher, PFQ 1315 impact crusher, HPY 300 hydraulic cone crusher,HPY500 hydraulic cone crusher, mobile jaw crusher, etc.

Features

1. To apply special waveform alloy jaw plate, so that the final size is granularity ,high efficiency and long life time of jaw plate.

2. Compared with traditional jaw crusher, the crushing cavity is deeper, which achieves the obvious advantages of big crushing ratio and big capacity.

3. DHKS series jaw crusher applies the strong swing structure of swing jaw and small tooth angle tip, which can be used to crush various hard rock, ore, especially the cobble.

4. Simple discharging adjustment, convenient operation and maintenance, stable running, convenient installation, low operation cost.

Working principle

When Stone jaw crusher works, electrical motor drives the belt wheel to make the swing jaw move following the specific track by eccentric shaft. After the materials enter into the crushing chamber, they are crushed between the two jaw plates by impacting, bending, and striking, and then discharged from the discharge opening.

Parameters

Price List of Stone Jaw Crusher

The price list depends on specific stone crusher types and models. As the leading manufacturer and exporter in China, we will provide maximum preferential factory price and discount for you. Our jaw crusher has been exported to Philippines, Malaysia, France, Japan, South Africa, Kenya, Nigeria, Ethiopia, Zambia, Namibia, Somalia, Nepal, Pakistan, Saudi Arabic and over 90 countries around the world.

Specification

Feed Opening Size

(mm)

Max. Feed Size

(mm)

Discharge Opening Size

(mm)

Capacity

(t/h)

Power

(kW)

DHKS1610

400×250

210

20-80

7-23

15

DHKS2416

600×400

340

40-100

25-64

30

DHKS3020

750×480

400

50-120

60-120

55

DHKS3624

920×600

510

65-130

88-170

75

DHKS4230

1060×750

640

65-200

90-310

110

DHKS4836

1220×910

770

90-250

200-500

160

DHKS5112

1300×300

240

20-90

30-110

75

DHKS6016

1500×400

320

25-90

60-200

90

Machine Photo

Customer Cases

2000t/h Limestone Production at Mengzi Country, Yunnan ProvinceThe main equipments: ZSW1860 vibrating screen, JC140 jaw crusher, PFQ1520 impact crusher, 3YK3280 vibrating screen, PFL1750 complex crusher, 2YK3073 vibrating screen.

600 t/h Limestone Production Line at Shanxi Province The main equipments: ZSW1860 vibrating feeder, JC140 jaw crusher, DHKS6016 jaw crusher, vibrating screen and electrical control system.

Keywords:

Get a quote

Note: Please leave your email address, our specialists will contact you as soon as possible!

Relevant Cases