Categories

Contact Us

Email :A.Alexandr@huazn.com

Phone/WhatsApp:

+7 903 008 6006

Address:

Moscow, Nizhegorodskaya Street 32s15, 5th floor, office 513

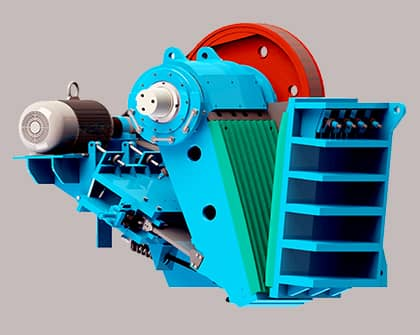

JC Jaw Crusher

Max. Feed Size: 0-1300 (mm)

Processing Capacity: 50-2000 TPH

Applied Material: Granite, marble, basalt, limestone, quartz, pebble, ore, etc.

Application Fields: metallurgy, mining, chemical, cement, construction, etc.

Customized Service: Small, medium and large models can be customized to meet your needs.

- Commodity name: JC Jaw Crusher

- Описание продукции

-

Description

The JC series Jaw Crusher is a new type of jaw crusher with optimized and developed design on structure, material selection, manufacture process and assembly, which is based on absorbing the international advanced technology and applying company's decades design concept and technology of jaw crusher. With the features of smart structure and excellent performance, JC jaw crusher is suitable for crushing all kinds of hard and abrasive rock and mineral ore. In order to meet the needs of different working conditions from the customers, JC jaw crusher can apply modular bolt connecting frame without welding.

Application of Jaw Crushers

1.For granite, quarry stones, rocks, aggregate, basalt, limestone, gold ore, iron ore, etc.

2.Common final output size:20-50mm, 60-80mm, 80-100mm, 100-150mm, etc.

3.Hot sale capacity: 60-100t/h, 150-200t/h, 200-300t/h, 300-400t/h, 600-800t/h etc.

★Huazn manufactures 50-1400TPH coarse jaw crusher and fine jaw crusher in stationary type or mobile type.

Features

1. The structure design is suitable for crushing different kinds of minerals.

2. Optimal design of kinematics parameter and crushing chamber increase processing capacity and crushing performance.

3. The wedge adjustment for CSS achieves infinite adjustment, which is quick and convenient.

4. The bearing design ensures the big loading capacity and reliable operation of jaw crusher.

5. The design of toggle plate increases the stroke of lower chamber and processing capacity.

6. The integrated design of the motor base together with the main frame saves the installation space.

7. In order to increase JC jaw crusher crushing performance, various jaw plate tooth-shapes are suitable for different crushing materials.

Working Principle

When JC jaw crusher works, electrical motor drives the belt wheel to make the swing jaw move following the specific track by eccentric shaft. After the materials enter into the crushing chamber, they are crushed between the two jaw plates by impacting, bending, and striking, and then discharged from the discharge opening.

Parameters

Model Feed Opening Size(mm) Max. Feed Size (mm) Discharge Opening Size(mm)/Capacity (t/h) Power (kW) 40 50 60 70 80 90 100 125 150 175 200 225 250 275 300 JC80 800×510 430 50 55 80 90 110 120 135 170 200 240 75 70 85 100 125 145 170 185 240 280 330 JC90 900×600 500 80 100 120 140 160 180 210 260 300 90 110 120 140 170 200 220 280 330 360 JC100 1000×760 640 130 160 180 200 235 280 330 390 110 190 200 225 250 310 370 420 520 JC110 1100×850 720 180 200 220 245 300 350 400 460 110 240 265 295 320 385 455 520 590 JC125 1250×950 810 270 325 385 445 500 560 620 160 360 430 505 580 650 725 800 JC130 1250×1100 940 330 360 440 500 555 600 670 730 185 400 450 530 610 700 780 850 900 JC140 1400×1070 910 380 465 530 580 650 710 760 200 470 555 640 725 815 900 985 JC160 1600×1200 1020 490 550 635 710 780 855 930 250 640 730 825 920 1010 1105 1200 JC1613 1600×1300 1110 530 600 680 750 850 910 960 315 680 760 870 960 1100 1200 1300 JC2012 2000×1200 1020 600 670 750 830 950 1050 1150 355 730 900 1030 1150 1220 1300 1400 JC180 1800×1500 1300 700 810 930 1000 1080 1200 355 1000 1150 1300 1450 1600 1800 JC200 2000×1500 1300 750 860 960 1050 1150 1300 400 1100 1280 1500 1650 1850 2000 Remarks:

1.The capacity listed from the table is the corresponding parameters to crush the rock with the loose density of 1.6t/m³ (a feed material with an average specific gravity of 2.7t/m³).

2.The processing capacity shall be changed according to the different materials and different feeding.

3.The CSS refers to Closed Side Setting. The measuring method will be decided by the tooth profile of the jaw plates.

Machine Photo

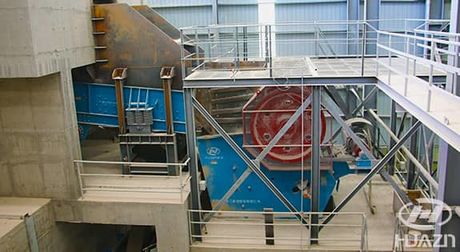

Customer Cases

2000t/h Limestone Production at Mengzi Country, Yunnan Province The main equipments: ZSW1860 vibrating screen, JC140 jaw crusher, PFQ1520 impact crusher, 3YK3280 vibrating screen, PFL1750 complex crusher, 2YK3073 vibrating screen.

600 t/h Limestone Production Line at Shanxi Province

The main equipments: ZSW1860 vibrating feeder, JC140 jaw crusher, DHKS6016 jaw crusher, vibrating screen and electrical control system.

Keywords:

Get a quote

Note: Please leave your email address, our specialists will contact you as soon as possible!

Relevant Cases