Categories

Contact Us

Email :A.Alexandr@huazn.com

Phone/WhatsApp:

+7 903 008 6006

Address:

Moscow, Nizhegorodskaya Street 32s15, 5th floor, office 513

ASJ-E Jaw Crusher

Max. Feed Size: 500-1000 (mm)

Feed Opening: 910×630,1070×760,1220×910,1370×1070,1520×1220 (mm)

Application Fields: mining, construction, metallurgy, cement, chemical industry

Applied Material: lime stone, medium-hardness iron ore, feldspar, etc.

- Commodity name: ASJ-E Jaw Crusher

- Описание продукции

-

Description

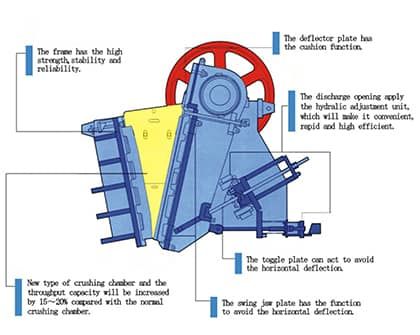

ASJ-E jaw crusher has the characteristics of high capacity, jaw plate wear resistance, high degree of humanized operation, good stability, simple structure and appearance which is the suitable choice for crushing processing with compressive strength less than 300 mpa.

Features

1.“V” type of crushing chamber, effective opening size is equal to the nominal opening size (common jaw crusher adopts the traditional asymmetric crushing chamber structure, and effective opening size is smaller than nominal opening size)and the throughput capacity will be increased by15-20% compared with the normal crushing chamber.

2.The discharge opening of ASJ-E jaw crusher applies the hydraulic adjusting unit, the optimized chamber and motion parameter make the product have greater through capacity for same clearance.

3.Smaller discharge clearance for same through capacity. The main components of frame adopt high- quality manganese steel, thickening steel plate, and finite element analysis method is used to evaluate mechanical strength in the process of design to improve the load resistance and impact during using. Cold installation process for bearing and thin oil lubrication make service life prolonged and efficiency of the rotation improved.

4.Four humanized maintenance operation units adopted for easily damaged parts of ASJ - E: bolt fastening and spring removal unit, moving jaw maintenance unit, side guard plate removal unit, adjusting seat replacement unit, so maintenance personnel can easily have inspection, maintenance and care with the four units.

Working Principle

When the jaw crusher works, the electric motor drives V-belt to make the swing jaw up and down through eccentric shaft. When the swing jaw goes up, the angle between toggle plate and swing jaw gets bigger, and the materials can be crushed. When the swing jaw goes down, the angle between toggle plate and swing jaw becomes smaller, the swing jaw moves away from the fixed jaw plate, and then the crushed materials will be discharged from the lower outlet of the crushing chamber.

Parameters

Model ASD

36-25

ASJ-E

42-30

ASJ-E

48-36

ASJ-E

54-42

ASJ-E

60-48

Max. Feed Siz (mm) 500 610 730 860 1000 Feed Opening Size (mm) 910×630 1070×760 1220×910 1370×1070 1520×1220 Css Discharge Opening/Capacity(t/h)

50 125 75 160 215 280 100 195 260 330 395 125 225 305 385 470 530 150 255 345 440 535 620 180 290 390 495 615 720 200 420 535 670 785 220 570 720 850 250 950 Power (Kw) 90 110 160 180 220 Machine Photo

Customer Cases

It is designed for granite crushing in Cameroon. The production capacity is 100-150t/h.

The main equipment: ZSW vibrating feeder, ASJ-E jaw crusher, GPY cone crusher, PLS vertical impact crusher, and YKR vibrating screen.

The production line is for granite crushing in Kenya, second purchase by the customer.

The main equipment: ZSW vibrating feeder, ASJ-E jaw crusher, PLS vertical impact crusher, and vibrating screen.

Keywords:

Get a quote

Note: Please leave your email address, our specialists will contact you as soon as possible!

Relevant Cases